At high temperatures plastic and composite bearings are subject to other problems such as softening , melting ,

deformation and may extrude out of the bearing area all together. Because the carbon graphite matrix is very strong.it is

not subject to the deformation , melting or even softening that can occur with plastic bearings at these elevated temperatures

Operating Temperature

The temperature resistance in an oxidizing atmosphere can be specified as 400o C maximum for G10

bearing qualities.in a non - oxidizing atmosphere the temperature resistance is determined by the final graphitizing treatment

of each individual grade ( e.g. upper application limit for graphite is approximately 3000o C ). temperature resistance

is also affected by various impregantions. in the case of resin impregnation the maximum operating temperature is 180o C

for lead impregantion 200o C and antimony impregnation 500o C

Frictional Behaviour

Graphite has self lubricating properties because of its crystalline structure. The low friction

coefficient is a function of the low bonding between the structural lattice planes. Dislocation of one against the other

is therefore easy. The friction coefficient is particularly low if traces of water or other vapours are present. The friction

coefficient is greatly increased when a vacuum is created. Because of varying conditions of application no exact data can be

given for friction coefficient. In general the following values can be expected for sliding friction :

- Dry friction 0.10...0.30

- Mixed friction 0.05...0.10

- Hydraulic friction 0.01...0.05

The frictional behaviour of carbon is also affected by the following factors :

- Running in

- Specific pressure

- Running speed

When Running in carbon and graphite bearings the friction coefficient drops until a constant value is reached once the surfaces are smoothed. The coefficient of friction also drops in the case of constant specific strain and increasing running speed or inverse.

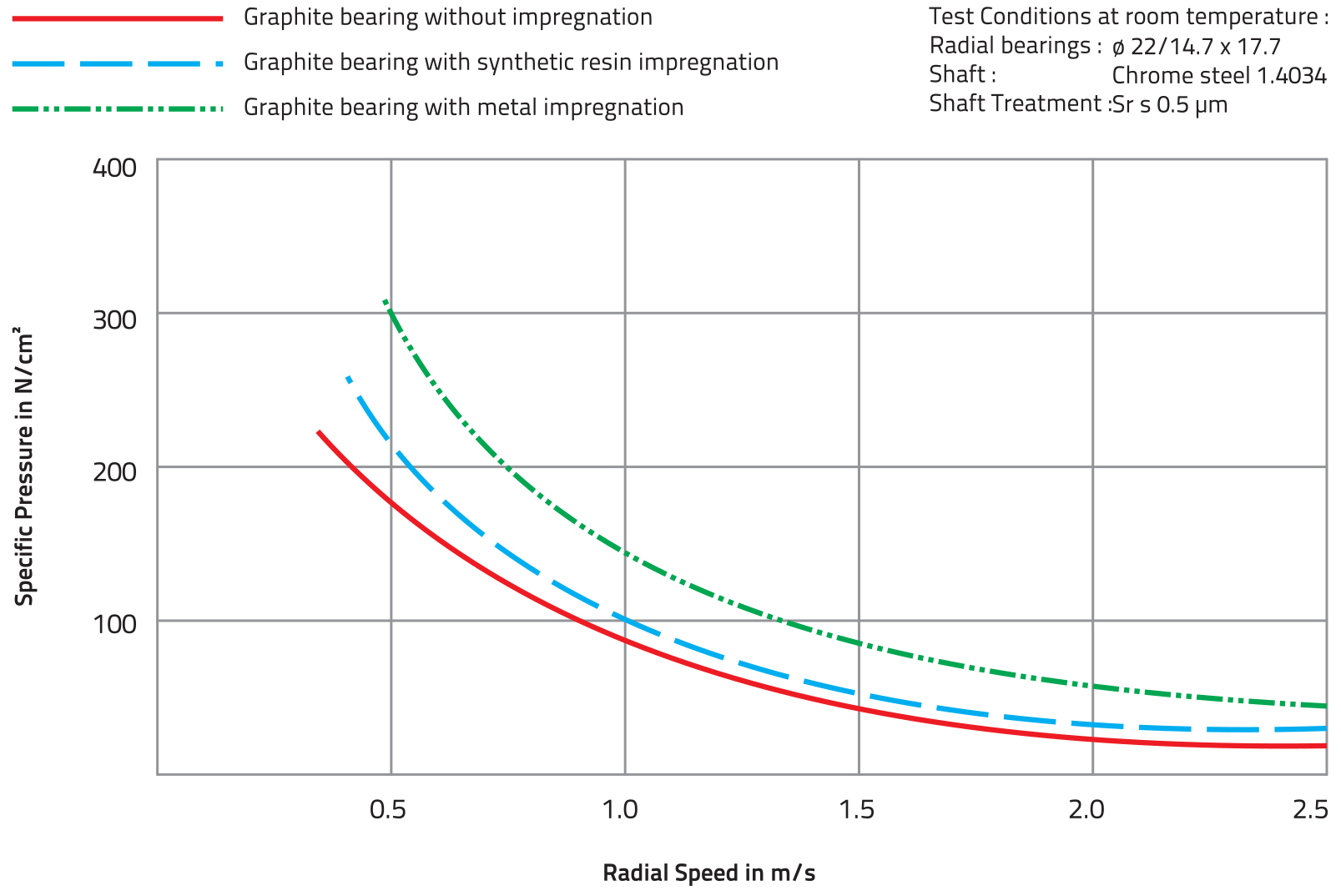

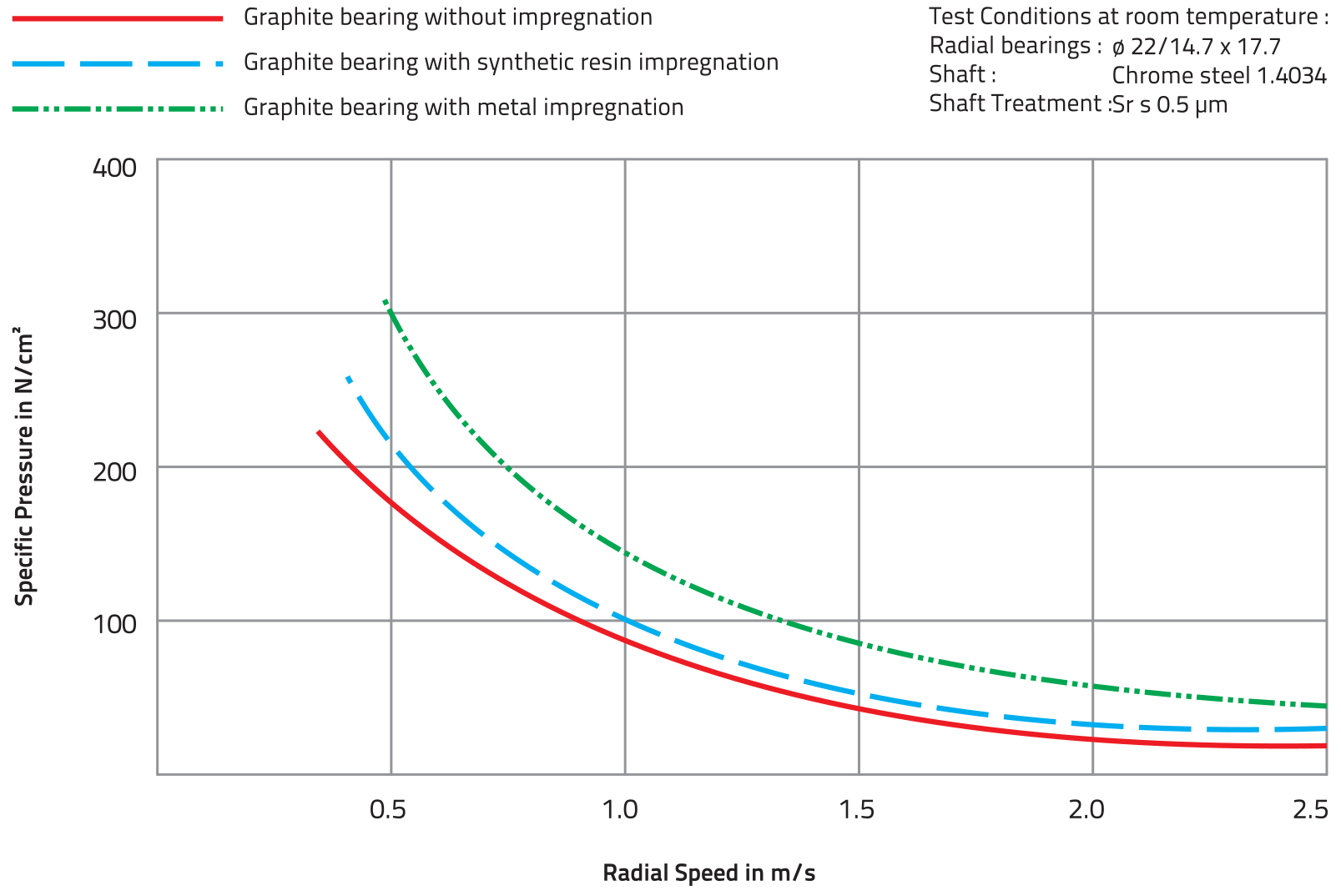

The permissible bearing pressure is determined by the surface speed of the shaft and the

friction ratio of the carbon or graphite bearings.The permissible pressure values for dry running bearings

have been determined by laboratory trials. The corresponding values can be seen in the following V-Diagram.

The permissible bearing wear rate was selected as 1(chrome steel) um/h. in practice the media often increases

lubrication. This means that the values in the P V-Diagram can be increases considerably whilst wear remains constant.

Advantages of using Carbon Thrust Bearing in Submersible Motors

- Helps the pump to run in dry condition.

- Low generation of heat due to self lubricating property.

When carbon is used as material for sliding purpose , there is no generation of heat in that area due to excellent

self lubrication available from carbon. This helps to improve the life of thrust bearing as well as other parts of

the pump which may be damaged due to high temperature.

- Contributes in saving of power.

As the electricity goes costlier day by day , carbon is the best solution for decreasing running cost of the pump.

- Runs with low input power as compared to ferro asbestos/teflon.

As ferro asbestos is a breaking materials it cause friction between the thrust pad and bearing resulting in higher requirements of

power where as the carbon causes a free movement and the pump starts & runs with minimum energy.

- The motor with carbon thrust bearing and bush does not seize even after prolonged rest.

Even if the pump is not i use for a long period the pump with carbon bearing starts immediately with the supply

of power

- The low hp pump with carbon provides same output as high hp pump with ferro asbesotos , teflon or nylon.

Due to excellent self lubricating properties of carbon there is no friction between the thrust pad and bearing and as result

there is no energy loss and so the pump gives the maximum output.

- The pump with carbon bearing starts at lower voltage compared to the pump with ferro asbestos or other bearing materials which require higher voltage to start.

As there is a shortage of electricity and problems of the voltage drop in the villages and urban areas , carbon enables the

pump to start at low voltage available whereas ferro asbestos or other materials fails to start the pump at low voltage of power.